Oil well electric submersible pumps technical description:

The downhole main components of the electric submersible pumps are:

Seal-chamber section; Induction motor (Three-phase), with /without a sensor package; Multistage centrifugal pump with either an integral intake or separate, bolt-on intake

The basic electric submersible pump system includes:

a) A surface control package.

b) A three-phase power cable running downhole to the motor.

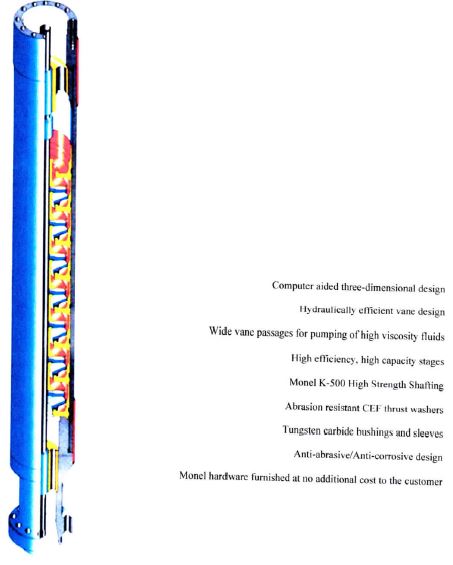

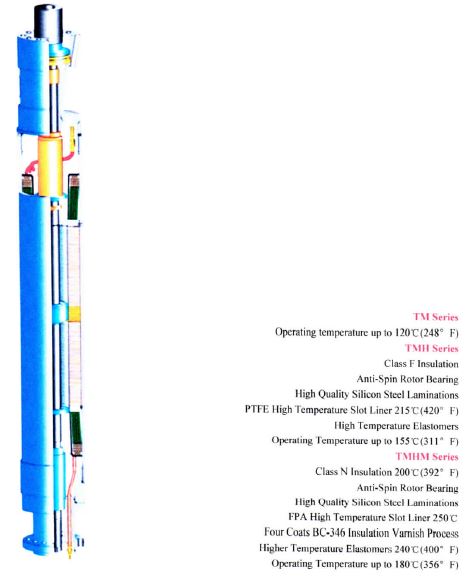

c) Motor: Maximization of the lift of the pump and the power output of the motor as a function of the diameter and length of the tool.

d) Seals Section.

e) Centrifugal pump: Under different applications, either the pump, seal, or motor can be multiple components connected in series.

The components are manufactured in lengths up to approximately 30 ft,

Advantages of ESP:

Applicable up to highly deviated wells, even horizontal.

Permit use of minimum space for subsurface controls and associated production facilities.

Quiet, safe, and environmentally conscious area.

High-volume production pumps.

Provides increasing volumes brought up by pressure maintenance and secondary recovery operations.

Allowing placing wells on production, while drilling in immediate vicinity.

Limitations of ESP:

Will tolerate minimal percentages of solids (sand) production. Special pumps with hardened surfaces and bearings are manufactured to minimize wear.

Costly pulling operations and lost production occur when correcting downhole failures, especially in an offshore environment.

Below an estimated 400 B/D, power efficiency drops sharply; ESPs are not suitable for rates below 150 B/D. Requires greater than 4½-in. outside diameter casing size for high-production-rate equipment.

Installation, handling, maintenance, and troubleshooting

Lufkin Rig Manufacturing, Inc. offers the Installation, handling, maintenenace and troubleshouting services for our customers anywhere in the world.

Proper installation and handling procedures are fundamental. Many factors can directly affect the run-life of an ESP system. The recommended handling procedures and installations are detailed in API RP11S3. Even so Lufkin RM should be contacted for specific recommendations on our equipment. Operating, maintenance, and troubleshooting recommendations are covered in API RP11S; a lot can be learned from the disassembly of the ESP components after they are pulled from the well. This is true whether they are in reusable condition or under heavy failure. The equipment and the wellbore always indicate items that can be changed or improved. API RP11S1 provides guidelines on the disassembly of ESP components and the evaluation of the findings, We at Lufkin RM have recommendations and guidelines on this topic.